The rapid evolution of Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs) has introduced powerful, yet potentially hazardous, high-voltage (HV) systems. Safety is the paramount concern in these systems, not only for the vehicle’s occupants but also for maintenance technicians and first responders. The High Voltage Interlock Loop (HVIL) is a critical safety mechanism designed to mitigate these risks.

What is HVIL?

HVIL Definition

The HVIL stands for High Voltage Interlock Loop. It is a low-voltage monitoring safety mechanism and the failsafe heartbeat of an electric vehicle’s high-voltage system. In essence, the HVIL is a continuous low-voltage loop that parallels the high-voltage circuitry. It uses a low-voltage signal to monitor all components connected to the high-voltage wiring harness in an electric vehicle. When the loop is broken or compromised, the system detects this and initiates protective actions. What’s more, the high-voltage terminals must connect before the low-voltage detection circuit and disconnect after it, with a specified time delay between the two actions.

Core Functions

The HVIL performs several vital functions:

- It verifies the continuity of all high-voltage connectors, wiring harnesses, and protective enclosures. A break or fault in the loop implies a disconnection or risk in the associated high-voltage circuit.

- It acts as a trigger mechanism: if the interlock loop opens, the system initiates a response—isolation of the high-voltage supply and a diagnostic fault code.

- It ensures that high-voltage power cannot be present when a connector or cover is open, or when the loop is compromised—reduction of the risk of arcing, shock, or inadvertent energization.

Purpose

The primary purpose of the HVIL is to enhance the vehicle’s electrical safety. It protects the safety of users, maintenance personnel, and first responders by preventing exposure to lethal high-voltage electricity.

Safety Standards and Certifications

Due to its special safety role, HVIL systems are strictly governed by international automotive safety standards. Compliance is mandatory for all road-going electric and hybrid vehicles. Relevant certifications and standards include:

- ISO 6469: International standard for safety specifications in EVs.

- ISO 26262: Functional safety standard for road vehicles, including electrical and electronic systems.

- UL 2580: Certification for battery safety in electric vehicles.

- SAE J1772 and IEC 62196: Standards covering high-voltage connector safety and design.

How Does HVIL Work?

Principles of The HVIL Circuit

The core principle of HVIL is the establishment of a low-voltage, closed-loop circuit that runs in series through all high-voltage components and connectors.

- Continuous Monitoring: A low-voltage signal (typically 12V) is injected into this auxiliary loop. The electronic control unit—usually the Battery Management System (BMS) or Vehicle Control Unit (VCU)—monitors the status of this signal at the end of the loop.

- Loop Closed (Normal): When all high-voltage connectors are properly mated and all high-voltage components are securely connected, the low-voltage interlock loop is complete. If the loop is closed, the system recognizes a safe condition. And it allows the high-voltage contactors (switches) to close, thereby energizing the main HV battery and drivetrain components.

- Loop Open (Fault): If any single component in the high-voltage path is removed, damaged, or improperly connected, the low-voltage HVIL loop will instantly break. This interruption causes the low-voltage signal to be lost or altered. The control unit detects it as an “open-loop” fault condition.

Key Components in HVIL Systems

The HVIL system consists of several crucial components:

| Component | Role in HVIL System |

|---|---|

| HVIL Connectors | Specialized connectors featuring interlock pins that are shorter than the main power pins |

| HVIL Pins | The actual low-voltage contacts within the connector that form the monitoring loop |

| Control Unit (BMS/VCU) | The ‘brain’ that monitors the low-voltage signal’s presence and controls the high-voltage contactors |

| High-Voltage Contactors (Relays) | Electric switches that receive the de-energization command from the VCU/BMS |

Step-by-Step Operation Process

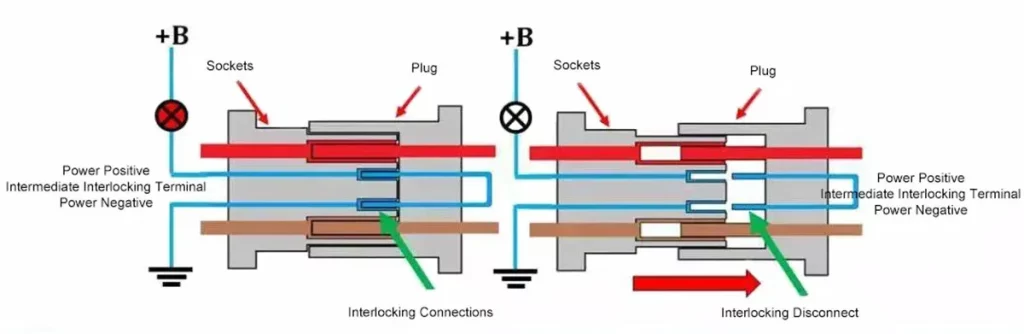

The High Voltage Interlock Loop ensures safety through a controlled sequence of connector engagement and disengagement.

Connection (Plugging In) Sequence

- High Voltage (HV) Contact: The main HV power terminals connect first.

- HVIL Connection: The shorter HVIL signal pins connect immediately after, completing the low-voltage monitoring loop.

- System Check: The control unit (BMS/VCU) validates the continuous HVIL signal.

- Power Enable: The control unit closes the main contactors, safely energizing the high-voltage system.

Disconnection (Unplugging) Sequence

- HVIL Break: The HVIL signal pins disconnect first, breaking the low-voltage monitoring loop.

- Fault Signal: The control unit instantly detects the open circuit.

- Power Disable: The control unit immediately opens the main contactors, de-energizing the high-voltage system.

- HV Disconnect: The main HV power terminals separate only after the power is removed, preventing arcing and ensuring safety.

How to install a high-voltage connector for Ev?

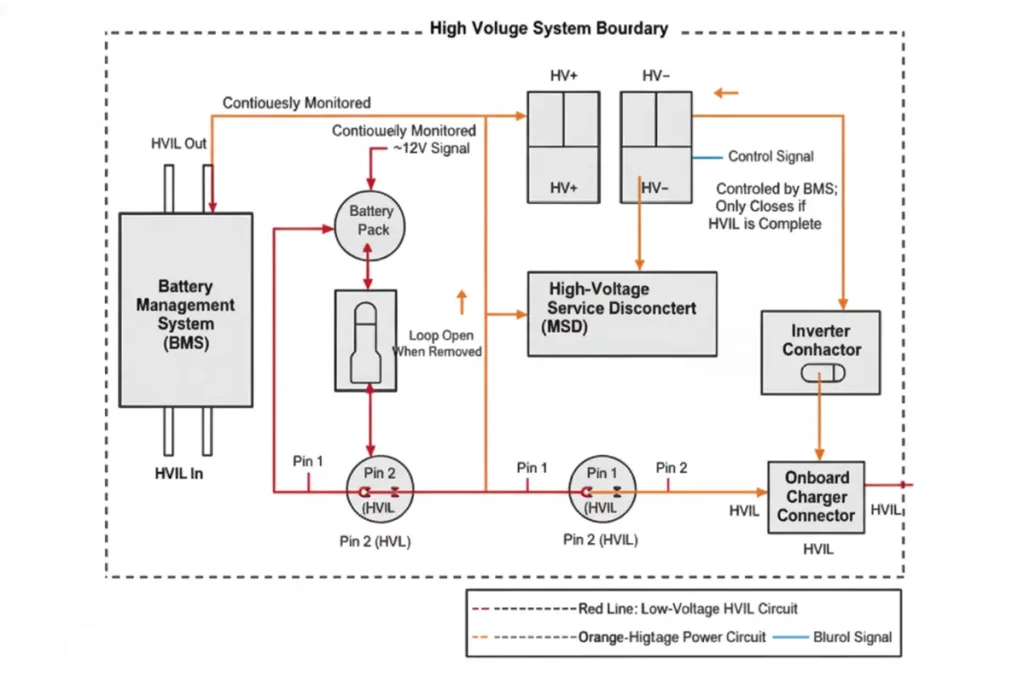

Example of HVIL Circuit in an Electric Vehicle

In the EV application, the HVIL circuit might run sequentially through:

BMS – Battery Pack Connector (Pins 1&2) – Manual Service Disconnect – Inverter Connector (Pins 1&2) – Onboard Charger Connector – Back to BMS

Diagram of HVIL circuit

Why Is It Important for EV Safety?

HVIL is a fundamental safety barrier in all electrified vehicles, providing multiple layers of protection.

Prevents Electric Shock

This is the most critical function. HVIL is designed to cut off the high-voltage power the instant a connector starts to separate. This safety measure eliminates the risk of an individual coming into contact with a live, high-voltage component. The rapid de-energization ensures the system meets the “touch-safe” standard required for EVs.

Protects Technicians and First Responders

In routine maintenance or post-accident scenarios, a disconnected or damaged high-voltage connector could leave the vehicle’s high-voltage system live and hazardous. The HVIL ensures that the system enters a safe state if a connector is opened or removed, protecting technicians and first responders.

Detects Faults and Disconnections

Loose or partially engaged high-voltage connectors can cause increased resistance, heat, arcing, and eventual failure. The HVIL loop detects these faults early by monitoring integrity to prevent catastrophic failures or vehicle downtime.

Prevents Accidental Vehicle Operation

If the interlock loop is not intact, the control system will inhibit vehicle operation and restrict high-voltage power. It can prevent scenarios such as inadvertent start-up with an unsafe connection. Therefore, this enhances overall system reliability and safety.

HVIL Connectors

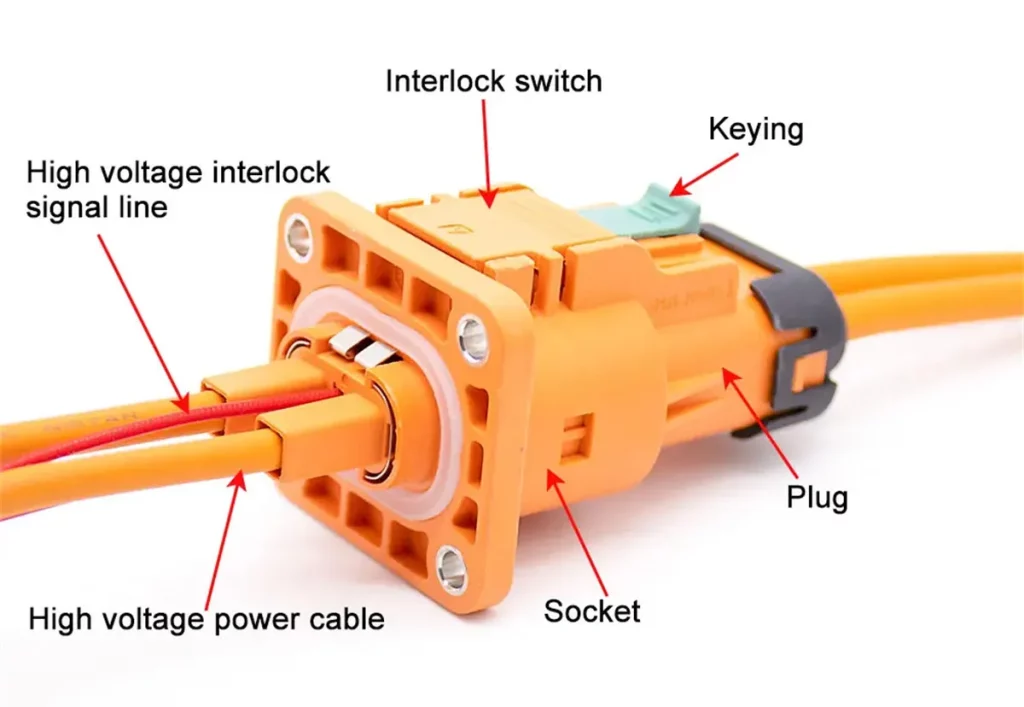

The high-voltage connector itself is the key component that implements the HVIL mechanism.

Design Structure and Materials

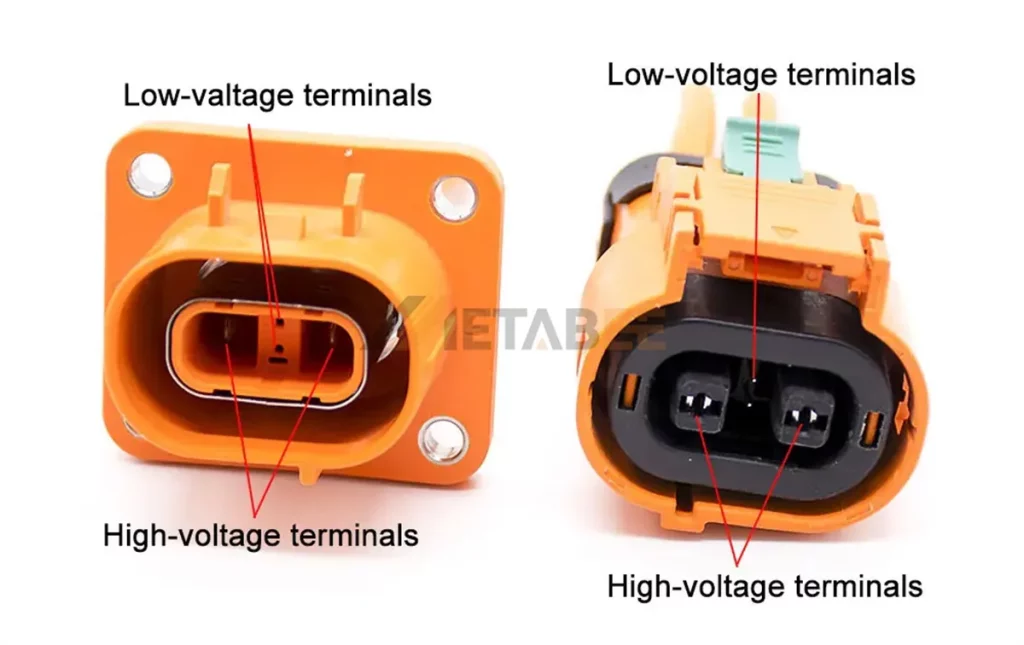

HVIL connectors are unique in that they integrate both high-voltage power contacts and low-voltage interlock contacts within a single housing.

The design structure typically include:

- Contacts : Made of high-conductivity Copper Alloy with silver or tin plating to minimize contact resistance and enhance current-carrying capacity.

- Interlock Pins: Shorter, dedicated low-voltage pins housed alongside the main power contacts.

- Shell: Constructed from PA66-GF flame-retardant thermoplastic materials, providing excellent insulation, heat resistance, and mechanical strength.

- Sealing and Shielding Components: Multi-layer seals and EMI shielding ensure the product achieves IP67/IP6K9K ratings for water and dust resistance. These features also guarantee excellent electromagnetic compatibility (EMC) performance.

- Locking Mechanism: Designed with ergonomic lever or push-pull locks to prevent accidental disconnection and ensure secure mating under vibration and thermal expansion conditions.

HVIL Connectors, source: Renhotec

Structure, materials and plating of HVIL connectors:

| Component | Material |

|---|---|

| Shell | PA66-GF |

| Contact Material | Copper Alloy |

| Contact Plating | Silver or Tin-Plated |

| IP Rating | IP67 / IP6K9K |

| Shielding | Shielded |

How to install HVlL Connectors Components & Best Practices for High Voltage Systems

Main Specifications

Key technical specifications for HVIL connectors include.

| Rated Voltage | 600V, 800V, 1500V |

| Rated Current | 16A to 250A |

| Insulation Resistance | > 200MΩ |

| Withstanding Voltage | 3000V AC |

| Durability (Mating) | < 500 Cycles |

| IP Rating | IP67 or IP6K9K |

| Flammability Rating | UL94V-0 |

| Operating Temperature: | -40°C to +125°C |

Applications

HVIL connectors are mandatory in all high-voltage connection points across various industries, primarily:

- Electric Vehicles (EVs/HEVs/PHEVs): Connecting the battery to the motor, inverter, onboard charger (OBC), DC/DC converter, and the charging inlet.

- Energy Storage Systems (ESS): Used in large-scale battery systems for grid power storage.

- Industrial Robotics and Machinery: Any high-power industrial application for personnel safety during maintenance.

- High-voltage accessories and subsystems: High-voltage heaters, compressors, power distribution boxes, and junction boxes all may use HVIL-enabled connectors to monitor integrity.

Why Choose Metabee HVIL Connectors?

Choosing the right High Voltage Interlock Loop (HVIL) connectors is crucial for ensuring the safety and reliability of any high-voltage system, particularly in electric vehicles (EVs). Metabee stands out as a superior choice due to a compelling blend of product excellence, manufacturing expertise, and customer-focused services.

Wide HVIL Product Range

Metabee offers a comprehensive portfolio of HVIL connectors, which includes straight, right-angled, and shielded variants. These designs are created to meet diverse applications and space constraints across the automotive and energy sectors.

Factory Manufacturing Advantages

Metabee manages its entire supply chain with in-house manufacturing, from raw material sourcing through production, assembly, and testing. This ensures traceability, consistent performance, and cost-effective scalability.

High-quality materials

Metabee’s HVIL connectors utilize high-conductivity copper alloy contacts and robust shielding. Their designs meet the demanding durability, thermal, and electrical standards necessary for e-mobility applications..

Technical Support and Customized Services

Metabee assists customers with technical guidance to specify the correct HVIL connector for their system. And this support includes customizing shell configurations, contact arrangements, interlock pin sequences, and cable assembly integration.

Conclusion

This comprehensive guide explains HVIL. It is a critical safety system in electric vehicles that prevents accidental electric shock. Simultaneously, it ensures the safe handling of high-voltage components.

This blog covers the HVIL introduction, how HVIL works, and its significance in EV safety. Furthermore, it also explores HVIL connector design, specifications, and applications, highlighting the advantages of Metabee HVIL connectors. In conclusion, HVIL is the non-negotiable backbone of EV safety.

Related Products

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the HVIL pins?

A: The HVIL pins’ primary function is to complete a low-voltage circuit loop that the vehicle’s control unit monitors. If the loop is broken, it signals the control unit to immediately cut off the main high-voltage power, preventing electric shock or arcing during connector separation.

Q2: Can an HVIL loop be used in stationary energy storage systems (ESS)?

A: Yes. While originally developed for EVs, HVIL architecture is applicable in stationary battery systems, where connector/disconnector safety is equally critical.

Q3: How does an HVIL connector differ from a standard high-voltage connector?

A: An HVIL connector includes dedicated interlock pins that are physically shorter than the main power pins. These shorter pins form the low-voltage HVIL circuit. Specifically, when a technician or component attempts to disconnect the connector, the shorter HVIL pins break contact before the main power pins do. This controlled sequence ensures the high-voltage circuit is safely shut down before exposure to live HV terminals is possible.

Q4: What are common failure modes for HVIL systems?

A: Common issues include broken or loose interlock wiring, unseated connectors, corrosion or wear on contact pins, incorrect mating sequence, damage to housings, or faults in the monitoring unit. Consequently, early detection via the interlock loop reduces the risk of major HV faults.

Q5: Does every high-voltage connector need an HVIL feature?

A: Yes. Any connection point that could expose a live high-voltage conductor to human contact or environmental elements—must integrate an HVIL mechanism to comply with safety standards.

Q6: Can HVIL connectors be customized for specific EV applications?

A: Yes. We can provide customized HVIL connectors tailored to specific voltage ratings, connector configurations, and environmental conditions. Thus, this allows OEMs to integrate HVIL systems seamlessly into their vehicles.