Among the various types of RF connectors, the N-type connector stands out for its robust design, high performance, and wide range of applications. In this article, we provide a comprehensive overview of N-type connectors, covering their dimensions, specifications, types, and selection guides.

What is an N-type Connector?

The N-type connector is a high-performance RF coaxial connector with a screw coupling mechanism design. Additionally, Its threaded design ensures a stable connection, making it suitable for high-frequency applications.

Definition

The N-type connector is a popular and robust coaxial RF connector that is primarily designed for high-frequency applications. It was originally designed and named in the 1940s by Paul Neill of Bell Labs.

Key characteristics of defining the N-type connector include:

- Threaded Coupling Mechanism: Ensures stable connections in high-vibration environments.

- Weatherproof Resistance: They are designed to be weatherproof, making them suitable for outdoor installations and harsh environmental conditions.

- Medium-Sized Design: Its medium size balances power handling capabilities with ease of use, making it a versatile choice for various applications.

- Air-Dielectric Interface: It utilizes an air-dielectric interface.

- Broad Frequency Range: Operating at frequencies up to 11 GHz.

Standard

- MIL-STD-348: It defines their mechanical and electrical specifications.

- IEC 60169-16: It specifies that the inner diameter of an outer conductor of N-type RF coaxial connectors is 7 mm (0.276 in).

- MIL-C-39012: It is another military specification that focuses on the general performance, assembly, and material requirements for RF coaxial connectors. It extends beyond the physical dimensions to address long-term operational reliability and environmental resilience.

These standards ensure compatibility and performance across different manufacturers and applications.

Design Mechanism and Materials

N-type connectors feature a threaded coupling mechanism, ensuring a secure connection and resistance to vibration. They are typically constructed from brass with nickel or gold plating for durability and low contact resistance. Furthermore, the insulation material is usually PTFE for stable electrical performance.

Materials and plating of N-type connectors:

| Shell | Brass |

| Shell Plating | Nickel-Plated |

| Contact | Brass |

| Contact Plating | Gold-Plated |

| Insulator | Teflon |

Dimensions

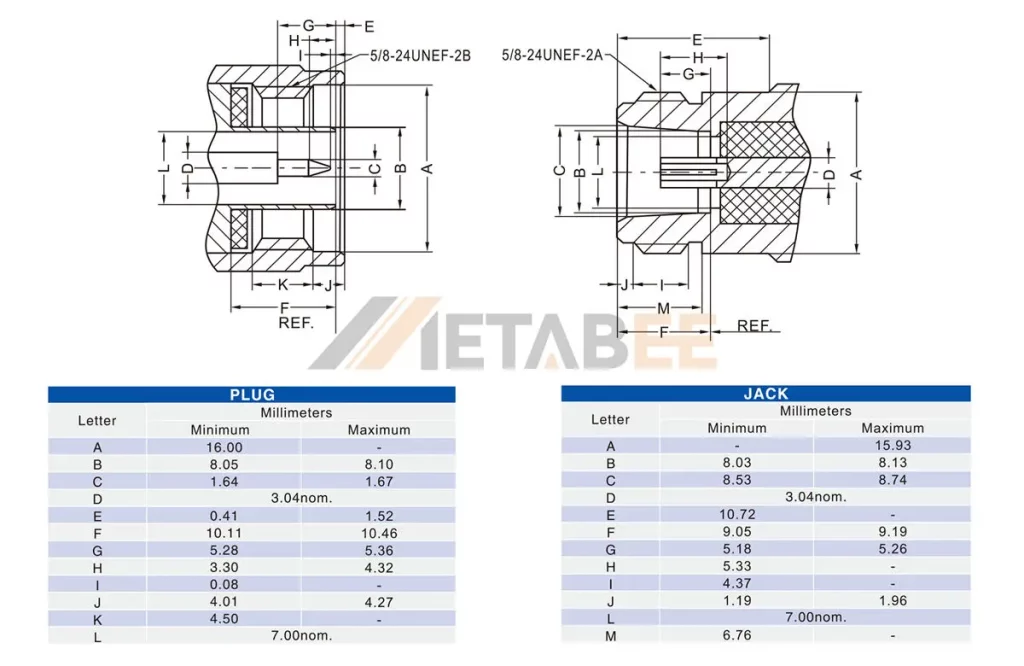

The dimensions of N-type connectors are essential for ensuring proper fit, reliable performance, and compatibility with various systems. Thus, these dimensions are standardized to maintain interoperability between different manufacturers.

Interface Diameter

N-type connectors follow precise mechanical dimensions to ensure compatibility.

- The threaded coupling: 5/8-24 UNEF-2A, 2B thread.

- The interface diameter of the N-type connector is 2.03 cm (0.80 in) for the male connector and 1.57 cm (0.62 in) for the female connector.

- The N-type connector has an inner diameter of the outer conductor of 7 mm (0.276 in).

Interface dimensions of N-type connector:

N-type Connector Specifications

Electrical Characteristics

N-type connectors are engineered to meet stringent performance standards across electrical, environmental, and mechanical parameters. Below is a detailed breakdown of their specifications.

- Impedance: The impedance of an N-type connector is 50 ohms.

- Frequency Range: N-type connectors are engineered to support high-frequency operations, ranging from DC to 11 GHz.

- IP Rating: N-type connectors are designed to meet IP65 standards.

- VSWR (Voltage Standing Wave Ratio): Straight type ≦ 1.3:1; right-angle type ≦ 1.5:1.

- Insulation Resistance: The insulation resistance of N-type connectors is ≥ 5000 MΩ, ensuring excellent electrical isolation.

Key electrical characteristics:

| Impedance | 50 Ohm |

| Frequency Range | DC to 11 GHz |

| IP Rating | IP65 |

| VSWR | Straight type ≤ 1.3 Right-Angle type ≤ 1.5 |

| Dielectric Withstanding Voltage | 2500 V rms |

| Working Voltage | 1000V rms |

| Center Contact Resistance | ≦ 0.2 MΩ (Milliohms MAX.) |

| Outer Contact Resistance | ≧ 5000 MΩ (Megohms MIN.) |

| Insulation Resistance | ≧ 5000 MΩ (Megohms MIN . ) |

Environmental Characteristics

N-type connectors are engineered to withstand harsh environmental conditions, making them ideal for indoor and outdoor applications.

- Temperature Range: N-type connectors can operate within a temperature range of -55°C to +155°C, making them suitable for harsh environments.

- Vibration: N-type connectors are designed to withstand mechanical vibrations without performance degradation. Specifications typically comply with MIL-STD-202 Meth. 204 standards.

- Corrosion Resistance: Main materials meet MIL-STD-202 Meth. 101 standards. Gold or nickel coatings protect N-type connectors against salt spray and harsh environments.

Critical environmental characteristics:

| Temperature Range | -55°C to +155°C |

| Vibration | MIL-STD-202 Meth. 204 |

| Corrosion Resistance | MIL-STD-202 Meth .101 |

Mechanical Characteristics

The mechanical design of N-type connectors prioritizes durability, user-friendly operation, and reliable mating cycles.

- Coupling: The threaded design provides superior mechanical stability, reducing the risk of accidental disconnection. The 5/8-24 UNEF thread design enhances durability and connection integrity.

- Durability: The mating cycle durability often exceeds 500 cycles, ensuring long-term reliability.

Main mechanical characteristics:

| Coupling | 5/8-24 UNFE Thread |

| Contact Retention | 6 lbs. MIN. |

| Coupling Nut Torque | 30 in-lbs. MIN. |

| Durability (Mating) | ≧ 500 Cycles |

6 Popular N-type Connector Types

We can divide it into 7 types according to gender, mounting method, and orientation.

By Gender

- N-type connectors come in two primary gender forms:

- Male N-type Connectors: There is an inter-threading, and the center contact is a pin.

- Female N-Type Connectors: There is an outer threading, and the center contact is a receptacle.

By Mounting Method

N-type connectors are available in various mounting configurations to accommodate different installation environments. According to the installation method, they can be divided into:

- Cable Type N-type Connectors: These connectors terminate coaxial cables and are available in crimp, solder, and clamp configurations.

- Panel Mount N-type Connectors: These connectors provide secure and stable connections. Based on the mount feature, N-type connectors can be categorized into 2-hole flange, 3-hole flange, 4-hole flange, and bulkhead connectors.

By Orientation

The physical orientation of N-type connectors influences their usability in specific mechanical layouts.

- Straight N-type Connectors: This is the most common form, providing a direct inline connection. Therefore, It is ideal for applications where space constraints are minimal and a straightforward cable route is possible.

- Right Angle N-type Connectors: They provide a 90-degree connection for space-constrained applications.

Applications of N-type Connector

N-type connectors are widely used in various applications, including:

- Telecommunications: Used in base stations, repeaters, and antenna systems

- Communication System: RF signal transmission in cellular base stations.

- Medical Equipment: RF testing in medical imaging systems.

- Test and Measurement Equipment: Provides reliable connections for spectrum analyzers, network analyzers, and other RF testing devices.

- Aerospace and Military: Due to their rugged design and high performance, they are often employed in demanding military and aerospace applications.

- Broadcasting: Connecting antennas and transmission lines.

SMA vs N-type vs BNC

Understanding the differences between various types of RF connectors is crucial for ensuring optimal performance and compatibility. I will compare N-type connectors with SMA and BNC connectors based on design, electrical performance, mechanical durability, and application scenarios.

SMA vs N-type Connectors

SMA and N-type connectors are both used for RF applications, but they differ significantly in size, frequency range, durability, and intended applications.

The key differences and similarities between the two connectors are as follows:

| Feature | SMA Connector | N-type Connector |

|---|---|---|

| Feature | SMA Connector | N-Type Connector |

| Full Form | Sub-Miniature Version A | N-type |

| Fastening Type | 1/4-36 UNEF Thread | 5/8-24 UNEF Thread |

| Frequency Range | DC to 18 GHz | DC to 11 GHz |

| Shell | Copper Alloy | Brass |

| Shell Plating | Nickel-Plated/Gold-Plated | Nickel-plated |

| Contact | Phosphor Bronze | Brass |

| Contact Plating | Gold-Plated | Gold-Plated |

| Connector Size | Smaller | Larger |

| Price | More expensive | More affordable |

| Insulator | Teflon | |

| Impedance | 50 Ohm | |

| Coupling method | Threaded Coupling | |

| Mounting | Available in cable-type, panel-mount versions | |

| Durability | ≧ 500 Cycles | |

N-type vs. SMA: SMA is better for compact, high-frequency applications, and N-type is ideal for rugged, high-power scenarios.

Related Posts

N-type vs BNC Connectors

BNC and N-type connectors serve different purposes in RF and low-frequency applications. BNC connectors prioritize quick connectivity, while N-type connectors emphasize robust performance and durability.

The main differences and similarities between the two connectors are as follows:

| Feature | N-type Connector | BNC Connector |

|---|---|---|

| Full Form | N-Type | Bsayonet Neill–Concelman |

| Mechanical Coupling | Threaded Coupling | Bayonet coupling |

| Impedance | 50 Ohm | 50 Ohm or 75 Ohm |

| Frequency Range | DC to11 GHz | DC to 4 GHz |

| Connector Size | Larger | Smaller |

| Shell | Brass | Copper |

| Shell Plating | Nickel-Plated | Nickel-Plated |

| Contact | Brass | Copper |

| Contact Plating | Gold-Plated | Gold-Plated |

| Price | Moderate | Lower |

| IP Rating | IP65 | |

| Mounting | Available in cable-type, panel-mount versions | |

| Insulator | Teflon | |

| Durability | ≧ 500 Cycles | |

| Application | Telecom, broadcasting, test equipment, video signals | |

N-type vs. BNC: N-type offers better performance and durability and BNC is more convenient for quick connections.

Related Posts

N-type Connector Selection Tips

Selecting the right N-type connector for your application requires careful consideration of technical specifications, environmental conditions, and compatibility requirements. Below are key factors to guide your decision-making process:

Frequency Range

You should ensure the connector’s specified frequency range meets or exceeds your system’s operating frequency to minimize signal loss and maintain signal integrity. Moreover, N-type connectors are designed for medium to high-power applications, typically operating up to 11 GHz.

Connector Type

Select the appropriate N-type mounting style (male type, female type, straight type, right angle type, cable-type type, panel mount type, and PCB mount) that suits your devices based on your application’s requirements. That can ensure the mounting method provides a secure and stable connection.

Environmental Conditions

You should consider the operating environment, including temperature, humidity, and exposure to moisture or corrosive substances. And choose N-type connectors with appropriate environmental sealing and materials to withstand the specific conditions.

Compliance and Standards

Verifying that the N-type connector you select complies with relevant industry standards (MIL-STD-348, IEC 60169-16, MIL-C-39012) to ensure interoperability and quality.

Cost vs. Performance

You need to balance budget constraints with performance needs. While higher-quality connectors may have a higher initial cost, they can provide long-term reliability and performance benefits. And also consider the total cost of ownership, including potential maintenance and replacement costs.

The Main N-type Connector Manufacturers

N-Type connectors are widely used across industries. As a result, several manufacturers have become top leaders in producing high-quality, reliable components.

Below is an overview of some top manufacturers in this field:

Amphenol: Amphenol is a global leader in interconnect solutions, renowned for its precision-engineered N-Type connectors.

TE Connectivity. TE Connectivity specializes in robust connectivity solutions for demanding applications.

Radiall. Radiall combines French engineering expertise with global manufacturing capabilities. So Its solutions are popular in defense, satellite, and medical imaging systems.

Metabee. Metabee is an emerging manufacturer specializing in cost-effective RF solutions, including a range of N-type connectors. We focus on providing reliable performance while maintaining affordability.

Renhotec. Renhotec is a leading provider of RF connectors and cable assemblies with a strong emphasis on high-volume production and custom solutions. Moreover, their N-type connectors are famous for versatility and cost efficiency.

Rosenberger. Rosenberger, a German-based manufacturer, is a key innovator in RF technology.

Conclusion

N-type coaxial connectors are critical components in RF and microwave applications. And their threaded coupling mechanism ensures secure connections. Consequently, they are the preferred choice for RF applications due to their superior performance, versatility, and long lifespan.

This article offers a comprehensive overview of N-type connectors, detailing their definition, standards, design, and dimensions. It dives into various performance specifications including electrical, environmental, and mechanical aspects. The discussion extends to different connector types based on polarity, mounting methods, and orientation, such as cable, panel, and PCB connectors. Additionally, I compare N-type connectors with SMA and BNC types, provides practical selection tips, and introduces major manufacturers.

Hope this article can help you confidently choose and utilize the right N-type connectors for your specific needs, maximizing performance and reliability.

Related Products

- N-type Connectors

- SMA Connectors

- BNC Connectors

- N-type Adapters

- SMA Adapters

- BNC Adapters

- SMA Cable Assemblies

- BNC Cable Assemblies