In the realm of miniature RF connectors, MCX and MMCX connectors are essential components. Understanding the key differences between them is crucial for achieving optimal design performance and reliable product functionality. This post will compare MCX vs MMCX connectors in terms of size, applications, durability, and other key factors. We’ll also provide selection tips to help you choose the right connector for your needs.

Overview of MCX and MMCX Connectors

Both MCX and MMCX are types of coaxial RF connectors primarily used in applications where space is a premium and reliable signal transmission is paramount.

What is an MCX Connector?

An MCX (Micro Coaxial) connector is a miniature RF connector that follows the European CECC 22220 standard. Introduced in the 1980s, MCX connectors use a snap-on interface for quick and easy mating and un-mating, making them ideal for applications requiring frequent connections.

Key characteristics include:

- Impedance: 50 ohms

- Frequency range: DC to 6 GHz

- Interface type: Snap-on coupling

- Size: Outer diameter of approximately 3.6 mm (0.14 in)

Metabee provides various MCX connectors, including

What is an MMCX Connector?

An MMCX (Micro-Miniature Coaxial) connector is an even smaller version of the MCX, developed in the 1990s and designed for ultra-compact RF applications. It aims to provide reliable signal transmission in devices with minimal space availability.

Key characteristics include:

- Impedance: 50 ohms

- Frequency range: DC to 6 GHz

- Interface type: Snap-on coupling with 360° rotation

- Size: About 2.4 mm (0.095 in) in outer diameter

Metabee offers a series of MMCX connectors, including

Key Differences Between MCX and MMCX Connectors

While closely related, MCX and MMCX connectors have several critical distinctions that influence their suitability for various applications.

Size and Form Factor

MCX connectors have an outer diameter of approximately 3.6 mm (0.14 in);

MMCX connectors have an outer diameter of approximately 2.4 mm (0.095 in), which is 30% smaller than that of MCX connectors.

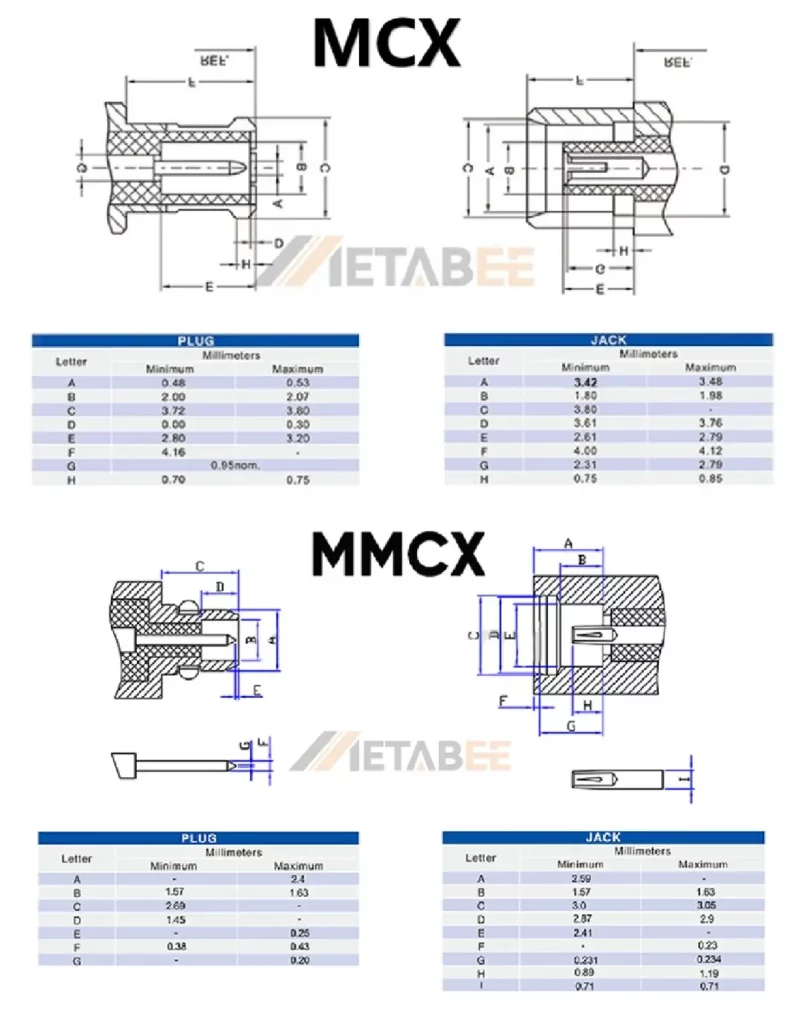

MCX vs. MMCX Interface Dimensions:

Coupling Mechanism

Both connectors feature a snap-on coupling mechanism, but there’s a subtle difference in flexibility. MCX connectors offer a standard snap-on push-pull coupling, but no rotational capability once mated. MMCX connectors provide a lock-snap mechanism that allows 360° rotation. This feature is particularly beneficial in tight spaces, allowing cables to be routed in any direction to improve flexibility.

Applications

MCX connector is used in applications where space is limited but not extremely critical, and durability and robustness matter, including:

- GPS Modules

- Automotive Systems

- RF Test Equipment

MMCX connector is preferred in space-critical, ultra-compact devices where minimal footprint and rotation flexibility are key, including:

- Small GPS Receivers

- In-Ear Monitors

- Mobile Phones

- Wearable Modules

Price

The MCX connector is cheaper. MMCX connectors are more expensive due to their compact design, higher precision requirements, and rotational features.

Durability

Both offer 500+ mating cycles, but the MMCX connectors’ locking design provides better long-term stability.

Environmental Performance

MCX connectors are more robust and better suited for industrial or outdoor environments.

MMCX connectors perform better in vibration-prone and space-limited mobile environments

MCX vs MMCX Comparison Table:

| Feature | MCX Connector | MMCX Connector |

|---|---|---|

| Size | Larger | More compact |

| Installation Rotation | Fixed | With 360° rotation |

| Insulator Material | Teflon | PTFE |

| Price | Cheaper | More expensive |

| Durability | More rugged, durable | More flexible, lower durability |

| Cost | More affordable | More expensive |

| Applications | GPS Modules, Automotive Systems, RF Test Equipment | Small GPS Receivers, In-Ear Monitors, Mobile Phones, Wearable Modules |

Similarities

Despite their differences, MCX and MMCX share several key features:

| Feature | MCX Connector | MMCX Connector |

|---|---|---|

| Coupling Mechanism | Snap-on coupling | |

| Impedance | 50 Ohm | |

| Frequency Range | DC–6GHz | |

| Body Material | Brass | |

| Body Plating | Gold Plating / Nickel Plating | |

| Contact Material | Brass | |

| Contact Plating | Gold Plating / Nickel Plating | |

| Insulator Material | PTFE | |

| Durability(Mating) | ≧ 500 Cycles | |

| Temperature Range | -65°C to +155°C | |

How to Choose Between MCX and MMCX Connectors?

When deciding between MCX and MMCX connectors, it’s essential to consider several factors that will impact your application, including frequency range, space constraints, budget, environmental conditions, and the required durability of the connectors. Below is a breakdown of the key considerations to guide your decision.

Frequency Range

Both MCX and MMCX perform well up to 6 GHz. For applications within this range, either could work from a frequency perspective.

Space Availability

- MMCX: If your design has extremely limited space and requires the smallest possible footprint, MMCX is the clear choice.

- MCX: If space is a concern but not to the absolute extreme, and you need a slightly more robust or easily handleable connector, MCX might be more suitable.

Budget

- MCX connectors are typically more affordable than MMCX connectors, as they are widely used in a variety of standard RF applications. This makes them a great option if you have budget constraints and don’t need the specific features of MMCX.

- MMCX connectors tend to be more expensive, reflecting their compact size, higher-frequency capabilities, and suitability for demanding applications.

Environmental Factors

Choose MCX for static or low-vibration environments where environmental exposure is minimal. MMCX connectors are ideal for situations where high reliability is needed, especially in environments with vibrations, frequent disconnections, or where durability is crucial.

Required Durability

- Choose MMCX when high mating cycles and rotational flexibility are necessary—ideal for applications like wireless communication and antenna systems that require repeated connections.

- Choose MCX for simpler, semi-permanent installations where connectors are rarely disconnected.

Conclusion

MCX and MMCX connectors are both excellent choices for RF applications demanding compact solutions. The fundamental difference lies in their size: MMCX offers a significantly smaller footprint, making it the go-to for ultra-miniature devices, while MCX provides a slightly larger, often more robust option for applications where space is limited but not critically constrained. By understanding their distinct features and commonalities, and by carefully evaluating your specific project requirements in terms of size, application, and durability, you can confidently select the perfect connector to ensure optimal performance and longevity for your electronic designs.

Related Products

FAQs

Q1: Are MCX and MMCX connectors interchangeable?

A: No, MCX and MMCX connectors are not interchangeable due to differences in size and mating interfaces. MCX connectors are larger and use different mechanical dimensions compared to MMCX connectors.

Q2: What is the main difference between MCX and MMCX connectors?

A: The primary difference lies in their size and use case. MCX connectors are slightly larger and typically used in applications with more installation space, while MMCX connectors are micro-sized and ideal for compact, high-density layouts.

Q3 What is the typical impedance of MCX and MMCX connectors?

A: Both MCX and MMCX connectors most commonly have a 50 Ohm impedance, which is standard for RF and wireless communication.

Q4. Do they support the same frequency range?

A.Yes. Both support DC to 6 GHz; check each product spec for exact bandwidth and VSWR

Q5:Are MCX and MMCX connectors waterproof?

A: Neither standard version is waterproof, but IP-rated or sealed variants are available for both MCX and MMCX connectors to protect against moisture and dust.

Q6: Which connector is better for outdoor or harsh environments?

A: The MCX connector is often preferred for harsher environments due to its better mechanical stability and resistance to vibration. However, both can be found in IP-rated or ruggedized versions for use in outdoor environments.