In most industrial applications, seamless communication and data transmission are critical. The significance of dependable connectors cannot be overstated. The versatility, durability, and standardized design of the M12 connector make it a popular choice in various industries, including automotive, manufacturing, telecommunications, and aerospace.

With a 12mm locking thread interface, M12 connectors provide a secure connection that can tolerate vibrations, shocks, and environmental extremes. This robust construction, together with standardized specifications, ensures interoperability and compatibility across different systems and devices.

In this post, we’ll dive into the M12 connector, exploring its definition, specifications, applications, and the reasons behind its widespread adoption. Understanding the principles of the M12 connector enables experts across industries to make informed decisions about its use in their systems, ensuring seamless connectivity and optimal performance.

What is an M12 Connector?

Definition

M12 connectors, also known as M12 circular connectors or M12 sensor connectors, are a type of metric circular connector with a 12mm locking thread interface. This interface ensures a secure and robust connection. So, M12 connectors are ideal for applications requiring high reliability.

The M12 connector is one of the M series circular connectors identified by the diameter of its outer threads. This series includes various connectors, including M5, M8, M16, and M23. Metabee can provide all types of M-series connectors.

History of M12 Connector

Lumberg, a German connector company, first introduced M12 connectors in 1985. It sought to develop a dependable, space-saving system for connecting sensors and actuators. Thus, the initial versions of M12 connectors were designed for industrial automation applications.

As the reliability and benefits of M12 connectors became evident, their usage expanded into other industries such as automotive, aerospace, and telecommunications. In 2003, the International Electrotechnical Commission (IEC) published the standard IEC 61076-2-101. The IEC’s standardization of M12 connections increased their popularity and made them the preferred choice for many applications.

Over the years, M12 connectors have seen significant technological advancements. These advancements include introducing shielded versions, high-speed data transmission capabilities, and custom configurations. They have made M12 connectors suitable for various applications, from power transmission to Ethernet communication.

Standards

IEC is the organization responsible for establishing standards related to the M12 connector. It published the original standards in 2003. These standards are currently in their third revision. In 2021, the IEC published the standard IEC 61076-2-010:2021. It’s a new push-pull M12 standard.

The standards for M12 connectors include:

- IEC 61076-2-101:2012 M12 connectors with screw-locking: M12 A, B, C, D and P-coding

- IEC 61076-2-109:2014 M12 connectors with screw-locking for data transmission frequencies up to 500 MHz: M12 X and H-coding

- IEC 61076-2-111:2017 M12 power connectors with screw-locking: M12 E, F, K, L, M, S, T-coding

- IEC 61076-2-113:2017 M12 connectors with screw-locking, power and signal contacts for data transmission frequencies up to 100 MHz: M12 Y-coding

- IEC 61076-2-010:2021 Connectors with outer or inner push-pull locking mechanism, based on mating interfaces according to IEC 61076-2-101, IEC 61076-2-109, IEC 61076-2-111 and IEC 61076-2-113

Metabee manufactures M12 connectors according to these standards with high-quality materials.

Advantages of M12 Connector

The M12 connector has numerous features that make it a popular choice for various applications.

Here are some main features:

- Robustness: One of the primary advantages of the M12 connector is its robust construction.

- Versatility: M12 connectors have various configurations, including codes, pin counts, and mounting options. This versatility enables engineers to choose the best connector variation for their unique application needs.

- Standardization: Our M12 connector meets the worldwide standards established by the IEC. This standardization enables compatibility and interoperability between various systems and devices. It permits the smooth integration and interchangeability of M12 connections from multiple manufacturers.

- Ease of Installation: M12 connectors have a simple plug-and-play design that allows for quick installation and maintenance. The threaded coupling mechanism ensures a secure and stable connection, while the compact design enables installation in limited spaces.

- Reliable Performance: M12 connectors provide dependable performance in harsh environments because of their secure locking mechanism and robust construction. They can withstand vibrations, shocks, and temperature swings while maintaining signal integrity and electrical continuity. Additionally, shielded versions of M12 connectors serve to reduce electromagnetic interference, ensuring uninterrupted transmission of data in noisy industrial situations.

Main Specifications

The main specifications of M12 connectors include various aspects of their design, construction, and performance characteristics. Understanding these specifications is critical for choosing the most suitable connector to meet specific application requirements.

Here are the main specifications for M12 connectors:

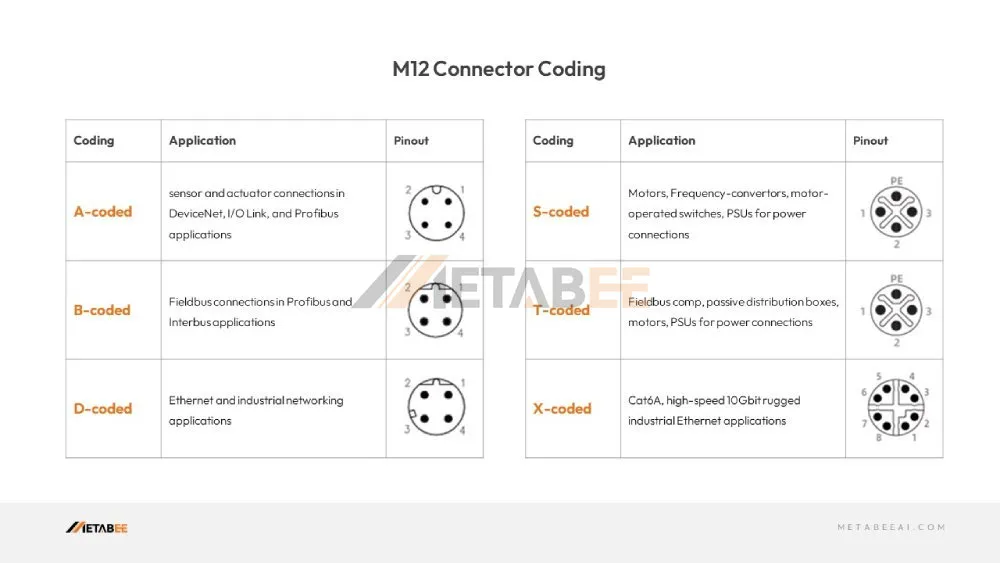

Coding

M12 connectors are available in different coding configurations, identified by letters like A, B, D, and X. Each coding scheme serves a specific purpose and determines the pin assignments and characteristics of the connector.

Here are the main codes and their applications:

- M12 A-coded connectors: Connecting sensor and actuator connections in DeviceNet, I/O Link, and Profibus applications;

- M12 B-coded connectors: Fieldbus connections in Profibus and Interbus applications.

- M12 D-coded connectors: Ethernet and industrial networking applications.

- M12 S-coded connectors: Motors, frequency converters, motor-operated switches, and PSUs for power connections. The rated voltage is 620V, and the rated current is 12A.

- M12 T-coded connectors: Fieldbus comp, passive distribution boxes, motors, and PSUs for power connections. The rated voltage is 63V, and the rated current is 12A.

- M12 X-coded connectors: Cat6A, high-speed 10Gbit rugged industrial Ethernet applications according to the standard IEC 61076-2-109.

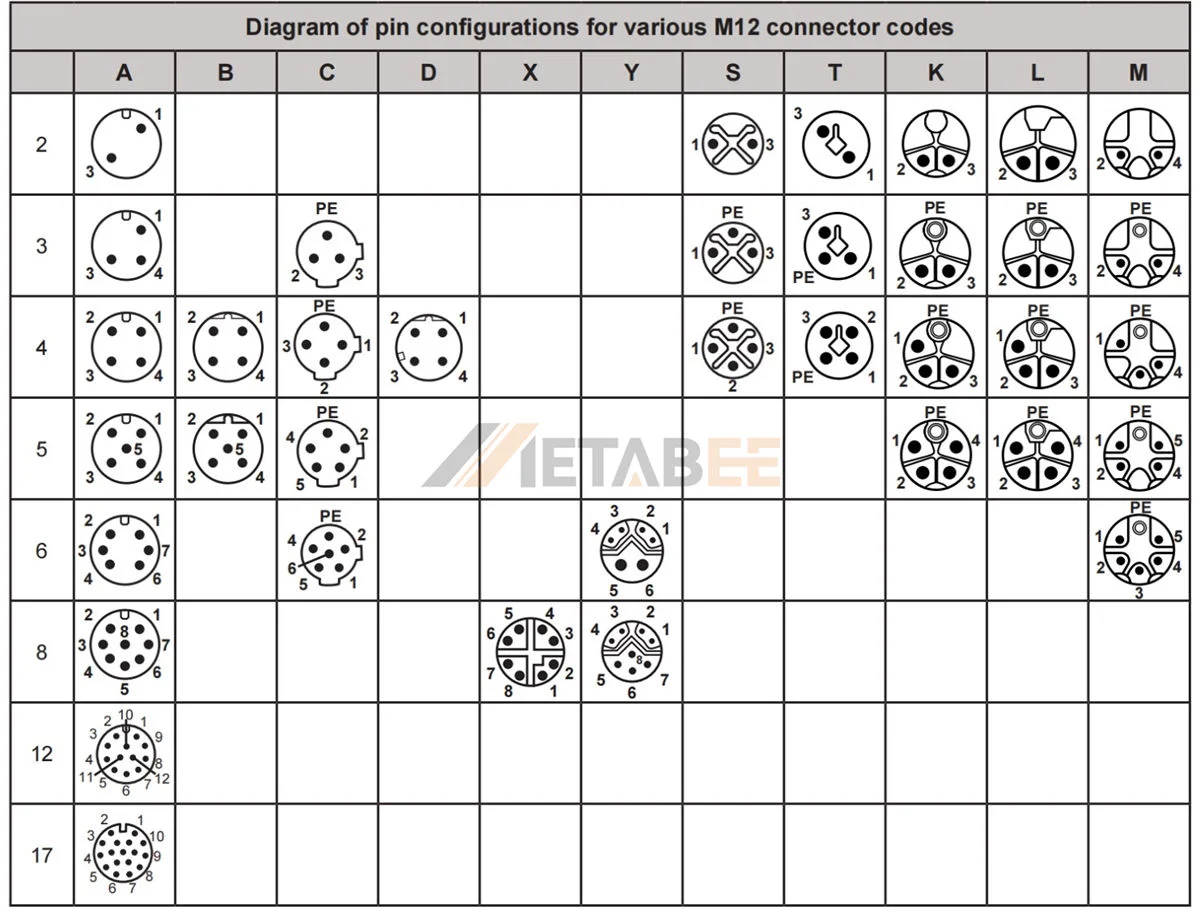

Pins

M12 connectors have various pin configurations, ranging from 2 to 17 pins. The number of pins determines the amount of signals or power that can be transferred through the connector. Common pin configurations include 3-pin, 4-pin, 5-pin, 8-pin, and 12-pin variants.

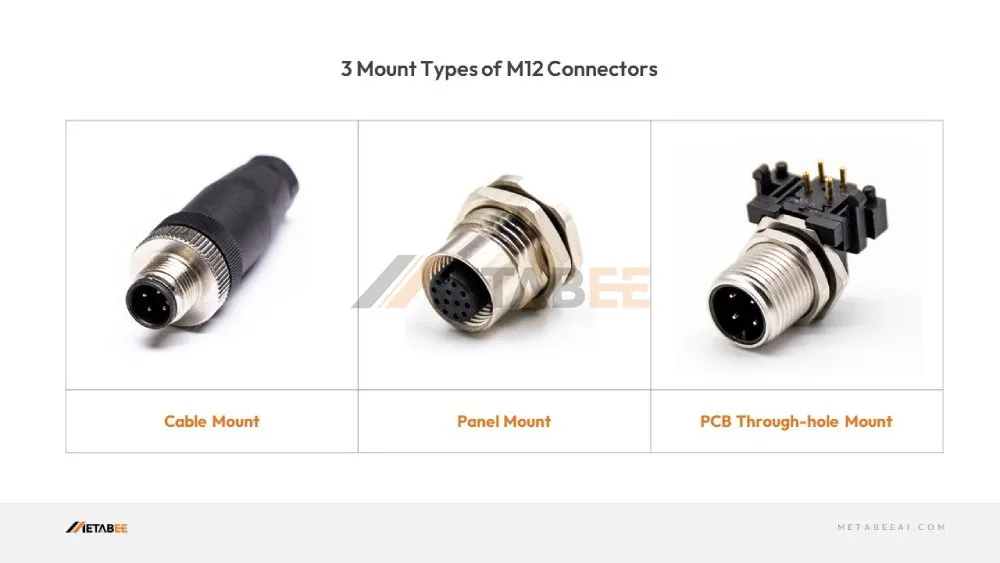

Mounting Type of M12 Connector

M12 connectors are available in various mounting types to meet different installation needs. The three major mounting options are:

- Cable mount: M12 cable connectors are attached directly to the end of the cables. There are two types of cable mounts: screw joints and soldering. M12 field wireable connectors always have a screw joint termination.

- Panel mount: M12 panel mount connectors are suitable for mounting on a panel or enclosure. There are two kinds of panel mounts: bulkheads and 4-hole flanges.

- PCB through-hole mount: M12 PCB connectors always have a through-hole mount termination.

Materials

The materials used in the construction of M12 connectors have a significant impact on their longevity, dependability, and performance. Manufacturers select materials based on factors such as environmental conditions, mechanical requirements, and application-specific needs.

Here are some common materials used in the construction of M12 connectors:

Metal Alloys:

- Stainless Steel: Stainless steel is a popular choice for M12 connector housings and coupling nuts due to its excellent corrosion resistance and mechanical strength.

- Brass: Brass is another commonly used material for M12 connector components, including contacts and coupling nuts.

Plastics:

- Polyamide (PA): Polyamide, commonly known as nylon, is frequently used in M12 connector housings and insulating materials.

- Polybutylene Terephthalate (PBT): PBT is a thermoplastic polymer known for its excellent electrical insulation properties and dimensional stability.

Elastomers:

- Silicone: the materials of M12 connector seals and gaskets are always silicone elastomers. because they can provide a reliable barrier against dust, moisture, and environmental contaminants.

- Ethylene Propylene Diene Monomer (EPDM): EPDM rubber is known for its excellent weather resistance, UV stability, and electrical insulation properties.

IP Rating

M12 connectors’ IP rating indicates the level of protection against dust, moisture, and other environmental contaminants.

Metabee’s M12 connectors are available in IP67 and IP68 versions:

- IP67: An IP67-rated M12 connector offers complete protection against dust ingress and can withstand immersion in water up to 1 meter deep for 30 minutes.

- IP68: An IP68-rated M12 connector offers complete protection against dust ingress and can withstand immersion in water up to 1.5 meters deep for 30 minutes.

Suitable Cable for M12 Connector

M12 connectors are compatible with various cables to meet different application needs. Cable options include twisted pair cables, Ethernet cables, and power cables, with varying conductor sizes, insulation materials, and shielding configurations.

There are 3 types of cables used for M12 connectors:

- Twisted Pair Cables: Data transmission applications, such as Ethernet networks and Fieldbus communication.

- Ethernet Cables: Ethernet applications, requiring cables that support high-speed data transmission.

- Power Cables: Power distribution applications, requiring cables capable of carrying higher currents.

Ruggedization

Ruggedization is a key feature of M12 connectors, particularly in situations where they are exposed to harsh environmental conditions, mechanical stress, and extreme temperatures.

Here are some essential aspects of ruggedization in M12 connectors:

- Reinforced Housings: M12 connectors may have reinforced housings made from durable materials like metal alloys or high-impact plastics.

- Strain Relief Mechanisms: These mechanisms may include integrated cable glands, strain relief boots, or over-molded cable assemblies.

- Corrosion Resistance: In corrosive environments where exposure to moisture, chemicals, or salt spray is a concern, M12 connectors may feature corrosion-resistant coatings or materials.

- Temperature Range: M12 connectors are designed to operate reliably over a wide temperature range, from -25℃ to +85 ℃.

- Impact and Vibration Resistance: M12 connectors undergo testing for impact and vibration resistance to guarantee they can withstand mechanical shock without loosening or disconnecting.

Current Rating

The current rating of an M12 connector is an important parameter that determines its ability to safely conduct electrical currents without overheating or sustaining damage. Understanding the current rating of M12 connectors is essential for selecting the appropriate connector to meet the application’s power requirements.

Applications of M12 Connectors

M12 connectors find widespread applications across various industries due to their versatility, reliability, and rugged construction.

Here are some main applications for M12 connectors:

- Industrial Automation: In industrial automation and control systems, M12 connectors play a crucial role in connecting sensors, actuators, and other devices to control units and PLCs (programmable logic controllers).

- Ethernet Networking: M12 connectors are widely used in Ethernet networking applications. They provide reliable connectivity for data transmission in industrial Ethernet networks, such as Ethernet/IP, Profinet, and EtherCAT.

- Fieldbus Communication: M12 connectors are commonly used in fieldbus communication systems, such as DeviceNet, Profibus, and CANopen. They can connect field devices and controllers in industrial automation networks.

- Transportation Systems: M12 connectors are widely used in transportation systems, including railway signaling, automotive manufacturing, and aerospace applications.

- Machine Vision and Robotics: In machine vision and robotic applications, M12 connectors can connect cameras, sensors, and actuators to industrial vision systems and robotic controllers.

- Renewable Energy: M12 connectors are used in renewable energy systems, such as solar power and wind turbine installations. They can connect sensors, monitoring equipment, and control devices.

- Telecommunications: In telecommunications networks, M12 connectors connect Ethernet switches, routers, and network devices in harsh outdoor environments.

M12 Connector Pinout, Color Code, and Wiring Diagram

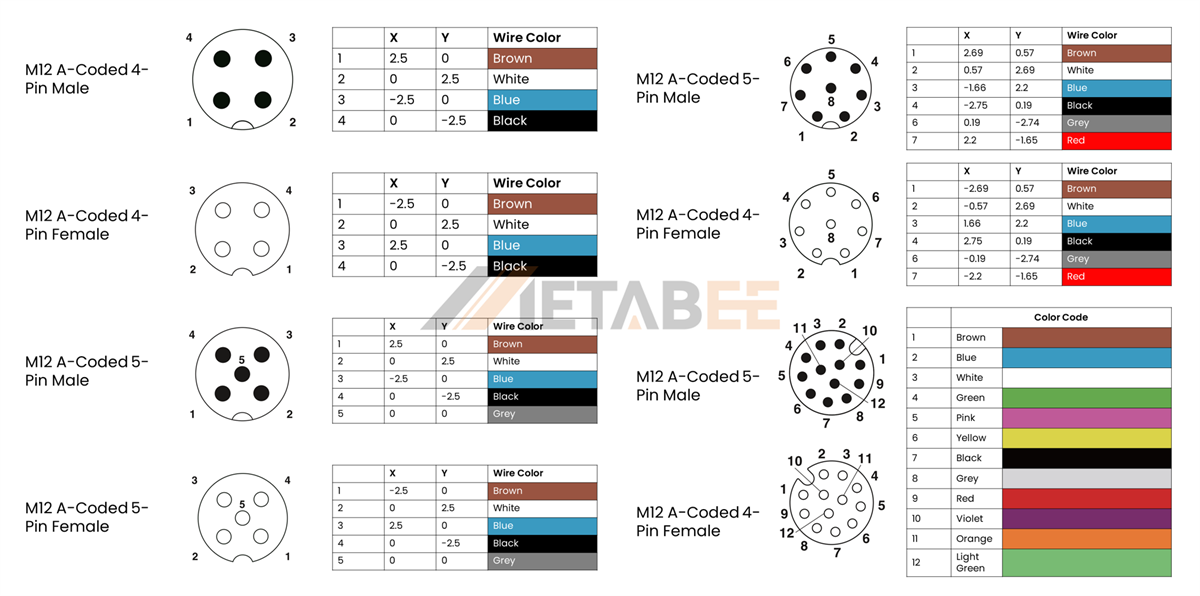

M12 connectors come in various codes, each with its own pinout and wiring configuration. Understanding the different codes and their corresponding pinouts is essential for proper installation and connectivity.

Pinout

The pinout of an M12 connector varies depending on its coding scheme. Here’s an overview of the pinouts for each type of M12 connector:

Color Code and Wiring Diagram

In addition to understanding the pinout of M12 connectors, you need to be familiar with the color coding used for the conductors in the cables. The color code provides a standardized way to identify and connect the wires, ensuring consistency and clarity in wiring installations.

Here’s an overview of the M12 color code, as well as a full wiring diagram for M12 connectors:

M12 Connector Manufacturers

When it comes to finding M12 connectors, several reputable manufacturers offer a wide range of options tailored to different applications and requirements.

Main Manufacturers

Here’s an overview of some well-known M12 connector manufacturers:

Why choose M12 connectors from Metabee?

Metabee is one of the most famous manufacturers in the M12 connector market. We have gained recognition for our innovative designs, high-quality products, and responsive customer service.

Here are some reasons to consider choosing M12 connectors from Metabee:

High-Quality Materials:

We manufacture M12 connectors with high-quality materials. They can withstand harsh environments, temperature extremes, and mechanical stress, providing long-lasting performance in demanding applications.

Responsive Support:

We are committed to providing excellent customer support and service. Our knowledgeable team is here to assist with product selection, technical inquiries, and custom solutions. We ensure a smooth and seamless experience for our customers.

Competitive Pricing:

Despite providing high-quality products and customization options, we maintain competitive pricing for M12 connectors.

Customization Options:

Metabee offers customization options for M12 connectors, allowing customers to tailor their connectors to their specific requirements. We support various demands and preferences, including custom cable lengths, codes, and other designs.

M8 vs M12 Connector

When it comes to industrial connectivity solutions, both M8 and M12 connectors offer robust connections for various applications. Understanding the differences between these two connector types is critical for selecting the best solution for your specific requirements.

Here’s a comparison between M8 and M12 connectors:

- Sizes: M8 connectors have a smaller form factor compared to M12 connectors;

- Locking thread: The standard thread of the M12 connector is 12mm, and the M8 connector uses an 8mm thread.

- Pin Count: M8 connectors typically have 3, 4, 5, 6, or 8 pins. M12 connectors have various pin counts, including 2, 3, 4, 5, 6, 8, 12, or 17 pins. So, M12 connectors allow for more versatile connectivity options.

- Coding: M12 connectors offer more coding options than M8 connectors, including A-coded, B-coded, D-coded, S-coded, T-coded, and X-coded variants. M8 connectors only have 2 coding options, A-coded and B-coded.

- Current Rating and Voltage: M8 connectors are designed for lower current and voltage ratings than M12 connectors. In comparison, M12 connectors offer higher current and voltage ratings, making them suitable for applications requiring power transmission or high-speed data communication.

M12 Adapters and Cable Assemblies

M12 adapters and cable assemblies are critical for extending the versatility and functionality of M12 connectors. They enable compatibility with different devices, interfaces, and wiring configurations.

Metabee can provide all kinds of M12 adapters and cable assemblies for our customers, including:

- M12 Y Splitters;

- M12 T Connectors;

- M12 to RJ45 Adapters;

- M12 to M12 Cable Assemblies;

- M12 to M8 Cable Assemblies;

- M12 to RJ45 Cable Assemblies;

- M12 to USB Cable Assemblies;

- M12 Pigtail Cables;

- M12 Molded Cable Assemblies;

- M12 Splitter Cable Assemblies.

Conclusion

M12 connectors are essential components known for their reliability and versatility across various industries. With standardized designs and robust construction, they ensure seamless connectivity in harsh industrial environments. Understanding their specifications, applications, and compatibility factors is crucial for choosing the right connectors.

Metabee is one of the most famous manufacturers of M12 connectors. We can provide high-quality products, fast support, competitive pricing, and customization options. Additionally, we can provide all kinds of M12 adapters and cable assemblies.

Related Products

- M12 Connectors

- M12 Adapters and Cable Assemblies

- Circular Connectors

- M8 Connectors

- M5 Connectors

- NMEA 2000 Cables and Connectors

Interesting article! M12 connectors seem like a versatile solution for industrial communication. Does Metabee offer any pre-assembled M12 cable assemblies with specific protocols like Profinet or EtherCAT?

Yes, we can offer these cable assemblies. Additionally, we can provide customized products according to your special requirements.

Pingback: M12 Connector Types: A Visual Guide for Identifying and Selecting - MetabeeAI

Pingback: The Ultimate Guide to M12 Connector Pinout and Wiring Diagram - MetabeeAI

Pingback: What is an M8 Connector? A Comprehensive Guide - MetabeeAI

Pingback: M8 vs M12 Connector: Everything You Need to Know - MetabeeAI

Pingback: M12 4-Pin Connector Pinout and Common Uses Explained - connector manufacturer

Pingback: Upgrade Your Industrial Network with the Right M12 Connector - connector manufacturer

Pingback: The 5 Non-Negotiable Parts for a Perfect NMEA 2000 Backbone - MetabeeAI